Key Takeaways:

- Precision machining offers enhanced accuracy, speed, efficiency, and cost-effectiveness.

- It enables the production of intricate designs and complex shapes while maintaining consistency and quality.

- Precision machining is widely used in industries such as aerospace, automotive, and medical.

- It is crucial for creating functional prototypes and end-use parts.

- CNC machining, a type of precision machining, eliminates the need for manual labor, increasing efficiency and productivity.

Increased Precision and Accuracy

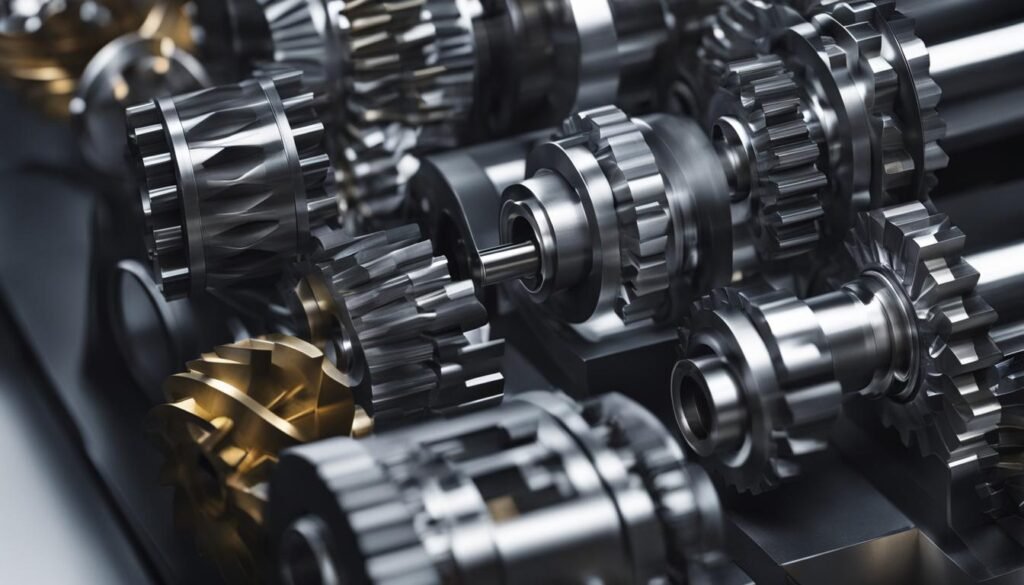

Precision machining, particularly high precision machining and precision engineering, offers unparalleled levels of precision and accuracy in the manufacturing process. With computer-controlled machinery and advanced measuring tools, every part produced meets the required specifications with utmost precision. This level of accuracy is crucial in industries where even the slightest deviation can lead to product failure or safety hazards. Precision machining ensures that each component is consistently and accurately manufactured, eliminating variations and ensuring optimal performance.“Precision machining allows for the production of complex and intricate components with tight tolerances, ensuring a perfect fit and optimal performance.”The use of computer-controlled machinery allows for precise measurements and controlled movements, resulting in accurate production. This precision machining technology enables businesses to produce intricate designs and complex geometries with ease. Whether it’s creating parts with tight tolerances or manufacturing intricate components, precision machining ensures every detail is accurately replicated. Overall, increased precision and accuracy in precision machining provide businesses with the confidence that each part manufactured meets the required specifications and performs flawlessly. The ability to achieve tight tolerances and precise fits among components ensures optimal functionality, reliability, and customer satisfaction.

Examples of High Precision Machining:

| Industry | Application | Benefits |

|---|---|---|

| Aerospace | Aircraft engine components | Improved fuel efficiency, reduced maintenance |

| Medical | Implants and surgical instruments | Enhanced patient safety and comfort |

| Electronics | Circuit boards and connectors | Reliable electrical connections |

Increased Efficiency and Productivity

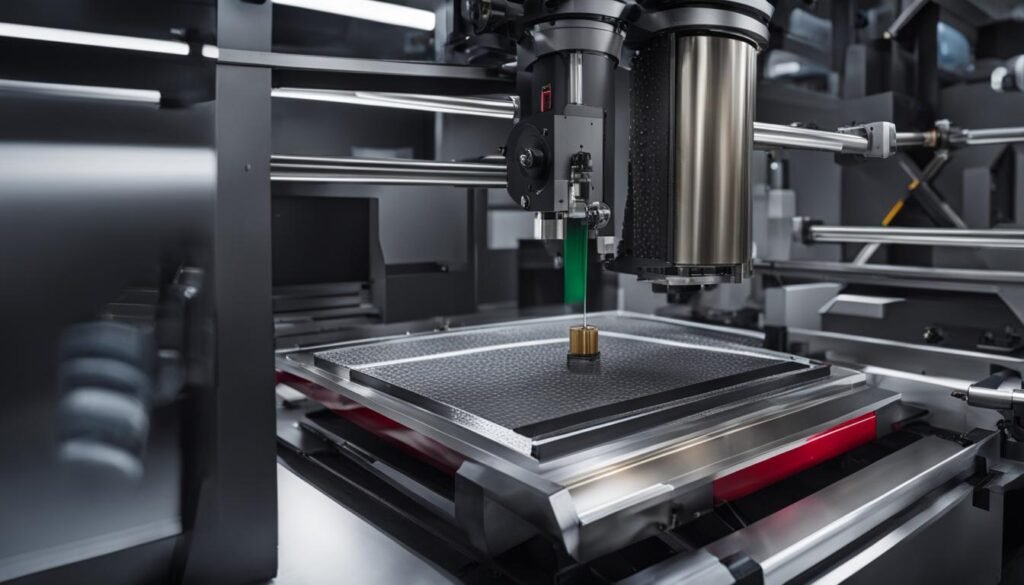

CNC machining, a type of precision machining, offers significant advantages in terms of efficiency and productivity. With computer-controlled machinery, manual labor is minimized, reducing the risk of errors and increasing production speed. CNC machines can operate 24/7, ensuring continuous production and faster turnaround times. This increased efficiency allows businesses to meet tight deadlines and handle large-scale production runs with ease. Additionally, precision machining solutions, such as automated tool changers and advanced programming capabilities, further enhance efficiency in the manufacturing process. By maximizing the utilization of CNC machines and utilizing advanced machining techniques, businesses can optimize their production processes and achieve higher productivity levels.Streamlined Workflow with CNC Machining

“CNC machining enables streamlined workflow by automating processes and eliminating manual labor. It reduces the risk of human error and increases production speed, resulting in improved efficiency and productivity.”“With the ability to operate 24/7, CNC machines ensure continuous production, allowing businesses to meet tight deadlines and handle large-scale production runs efficiently. The automated tool changers and advanced programming capabilities further enhance efficiency in the manufacturing process.”Whether it’s producing small-scale prototypes or mass-producing end-use parts, CNC machining provides businesses with the necessary tools to optimize their workflow, meet customer demands, and stay competitive in the market.

| Benefits of CNC Machining for Efficiency and Productivity | Explanation |

|---|---|

| Minimized manual labor | CNC machines reduce the need for manual intervention, minimizing the risk of errors and improving overall efficiency. |

| Continuous production | CNC machines can operate 24/7, ensuring uninterrupted production and enabling faster turnaround times. |

| Reduced lead times | With increased production speed and efficiency, businesses can meet tight deadlines and deliver products promptly. |

| Automated tool changers | CNC machines equipped with automated tool changers eliminate the need for manual tool changes, further streamlining the manufacturing process. |

| Advanced programming capabilities | The ability to program complex machining operations allows for faster and more efficient production runs. |

Enhancing Efficiency and Productivity with Precision Machining Solutions

Precision machining solutions offer advanced capabilities that further enhance efficiency and productivity in the manufacturing process. Automated tool changers allow for seamless and rapid tool changes, reducing downtime and maximizing machine utilization. Advanced programming capabilities enable the optimization of machining parameters, resulting in improved efficiency and reduced material waste. The integration of robotics and automation streamlines repetitive tasks, freeing up human resources for more complex operations. By leveraging precision machining solutions, businesses can unlock their full potential, achieving higher levels of efficiency, productivity, and overall success in the manufacturing industry.Improved Quality and Consistency

Precision machining plays a crucial role in improving the overall quality and consistency of manufactured parts. The use of computer-controlled machinery ensures that each part produced adheres to precise standards and specifications. This eliminates variations and inconsistencies that can arise from manual machining methods. Precision machining also reduces the occurrence of defects and errors, resulting in higher-quality end products. The ability to achieve accurate tolerances and tight fits among parts further enhances the overall performance and reliability of the products. One of the key ways precision machining improves quality and consistency is through its ability to produce parts with tight tolerances. CNC machines can achieve high levels of precision, ensuring that each part meets the required specifications with minimal deviation. This level of accuracy is crucial in industries such as aerospace and medical, where even slight deviations can lead to product failure or safety hazards. Precision machining also eliminates the human factor in the manufacturing process, reducing the risk of errors and ensuring consistent quality across all produced parts. Moreover, precision machining enables the production of complex and intricate designs with consistency. The computer-controlled machinery can accurately replicate intricate shapes and features, ensuring that each part is manufactured with precision. This capability is particularly valuable in industries that require specialized components, such as the automotive and electronics sectors. By eliminating variations and inconsistencies, precision machining ensures that every part meets the required specifications, resulting in products of the highest quality.| Benefits of Improved Quality and Consistency | Explanation |

|---|---|

| Reduced Defects | Precision machining reduces the occurrence of defects and errors, resulting in higher-quality end products. |

| Accurate Tolerances | Precision machining achieves high levels of accuracy, ensuring that each part meets the required specifications with minimal deviation. |

| Tight Fits | Precision machining enables the production of parts with tight tolerances, resulting in optimal performance and reliability. |

Cost-Effectiveness

Precision machining offers businesses significant cost-effectiveness in the manufacturing process. While the initial investment in CNC machinery and programming may seem substantial, the long-term savings outweigh the costs. Precision machining reduces labor costs by minimizing the need for manual labor and streamlining the production process. It also minimizes material wastage, as CNC machines can carefully and efficiently remove excess material, resulting in minimal scrap. The high precision and accuracy of precision machining reduce the occurrence of defects and rework, saving both time and resources. Overall, precision machining services provide businesses with cost-effective solutions that result in higher efficiency and better ROI.| Benefits of Cost-Effectiveness in Precision Machining | Example |

|---|---|

| Reduced Labor Costs | By minimizing the need for manual labor, precision machining significantly reduces labor costs. |

| Minimized Material Wastage | CNC machines carefully remove excess material, resulting in minimal scrap and cost savings. |

| Reduced Defects and Rework | The high precision of precision machining reduces the occurrence of defects and the need for expensive rework. |

| Improved Efficiency | Precision machining streamlines the production process, leading to better overall efficiency and time savings. |

Conclusion:

With the numerous benefits of precision machining, including increased precision and accuracy, improved efficiency and productivity, enhanced quality and consistency, versatility and customizability, and cost-effectiveness, it is clear that precision machining services are essential for businesses seeking growth and success in the manufacturing industry. The ability to achieve high-quality, precise parts while minimizing costs and optimizing processes makes precision machining a valuable tool in modern manufacturing. By leveraging the advantages of precision machining, businesses can unlock their full potential and stay ahead of the competition.Versatility and Customizability

Precision machining offers businesses a wide range of benefits, including versatility and customizability in the manufacturing process. One of the key advantages of precision machining is its ability to work with various materials, such as metals, plastics, and composites. This versatility allows businesses to choose the most suitable material for their specific application, ensuring optimal performance and functionality. Additionally, precision machining enables the production of intricate designs and complex geometries. This level of precision and detail provides businesses with the flexibility to create customized parts and components that meet their unique requirements. Whether it’s in the automotive, aerospace, or electronics industry, precision machining offers the ability to produce functional prototypes and iterate designs quickly, resulting in faster time-to-market. With precision machining, businesses can achieve the perfect balance between customization and scalability. They have the freedom to create tailored solutions while also benefiting from the efficiency and productivity of precision machining technologies. This adaptability is crucial in today’s dynamic and ever-changing market, where businesses need to stay competitive by meeting the evolving needs of their customers. Overall, the versatility and customizability of precision machining make it an invaluable tool for businesses across industries. Whether it’s producing complex components or designing intricate prototypes, precision machining offers the precision, flexibility, and efficiency necessary to unlock the full potential of modern manufacturing.

Overall, the versatility and customizability of precision machining make it an invaluable tool for businesses across industries. Whether it’s producing complex components or designing intricate prototypes, precision machining offers the precision, flexibility, and efficiency necessary to unlock the full potential of modern manufacturing.

Applications in Various Industries

Precision machining has widespread applications across various industries. Its versatility and precision make it an indispensable technology in modern manufacturing. Let’s take a closer look at how precision machining solutions are utilized in different sectors:Aerospace Industry

In the aerospace industry, precision-machined components play a crucial role in ensuring the safety and reliability of aircraft. From engine components to landing gear and structural parts, precision machining is used to create high-quality and precise parts that meet the stringent standards of the industry.Automotive Industry

Precision machining is widely used in the automotive industry for manufacturing engine components, transmission parts, and chassis components. The precision and accuracy offered by precision machining solutions ensure optimal performance and durability of vehicles.Medical Industry

In the medical industry, precision machining is instrumental in the production of implants, surgical instruments, and medical devices. The ability to create intricate and complex designs with high precision allows for the development of innovative medical solutions that improve patient outcomes.Electronics Industry

Precision machining plays a significant role in the electronics industry, where it is used to manufacture circuit boards, connectors, and housings. The precise and accurate production of these components is essential for the reliable operation of electronic devices.Other Industries

Precision machining also finds applications in industries such as defense, energy, and telecommunications. Its versatility allows it to be used across diverse sectors, meeting the unique manufacturing needs of each industry. Overall, precision machining solutions have a wide range of applications in various industries. The ability to create high-precision components with consistency, accuracy, and efficiency makes precision machining an indispensable technology in modern manufacturing.

Advancements in Precision Machining

Precision machining is a rapidly evolving field, constantly pushing boundaries and introducing cutting-edge technologies to enhance manufacturing processes. With the advent of advanced machining techniques, such as multi-axis CNC machines and high-speed machining, precision machining has become even more efficient and capable. These advancements have revolutionized the industry, offering businesses numerous benefits and opportunities. One of the key advantages of advanced precision machining is the ability to create complex and intricate designs with unparalleled precision. With computer-aided design (CAD) software, manufacturers can bring their ideas to life and produce highly detailed components. This level of customization allows businesses to meet the unique needs of their customers and deliver products tailored to specific applications. Another significant advancement in precision machining is the integration of automation and robotics. By incorporating automated processes, manufacturers can achieve higher levels of productivity and reduce human error. Automated tool changers and robotic arms enable continuous production, 24/7 operation, and faster turnaround times. This increased efficiency translates into cost savings and improved overall productivity.Advancements in Precision Machining

Additionally, advancements in tooling and materials have further improved precision machining capabilities. New cutting tools and materials with enhanced durability and performance help manufacturers achieve higher machining speeds and better surface finishes. This results in shorter production cycles and higher-quality end products. The future of precision machining holds even more exciting possibilities. Emerging technologies such as additive manufacturing, also known as 3D printing, are being integrated into precision machining processes. This combination allows for the production of highly complex and customized parts with reduced material wastage. Overall, advancements in precision machining have revolutionized the manufacturing industry, offering businesses increased precision, productivity, and versatility. As technology continues to evolve, precision machining will undoubtedly play a crucial role in shaping the future of manufacturing.

| Advancement | Benefits |

|---|---|

| Advanced machining techniques | Enhanced precision in complex designs |

| Integration of automation and robotics | Increased productivity and reduced human error |

| Advancements in tooling and materials | Improved machining speeds and surface finishes |

| Additive manufacturing | Customized parts with reduced material wastage |

Conclusion

Precision machining offers numerous benefits that can significantly amplify your business’s growth and success in the manufacturing industry. The advantages of precision machining include enhanced accuracy, increased efficiency, improved quality, and cost-effectiveness. With precision machining, you can achieve high precision and accuracy in the production of parts, ensuring that every component meets the required specifications. This level of precision is crucial to industries where even slight deviations can lead to product failure or safety hazards. In addition to precision, precision machining also brings increased efficiency and productivity to your operations. By utilizing computer-controlled machinery, you can reduce the risk of errors, increase production speed, and handle large-scale production runs with ease. This efficiency allows you to meet tight deadlines and streamline your manufacturing process. Furthermore,precision machining improves the overall quality and consistency of your manufactured parts. With the use of computer-controlled machinery, each part adheres to precise standards and specifications, minimizing variations and eliminating defects. This results in higher-quality end products that provide reliable performance. Lastly, precision machining is a cost-effective solution for your business. While the initial investment may seem substantial, the long-term savings outweigh the costs. Precision machining reduces labor costs, minimizes material wastage, and decreases the occurrence of defects and rework. These cost-saving benefits result in higher efficiency and a better return on investment. Embracing precision machining in your manufacturing processes is a key step towards unlocking the full potential of modern manufacturing. By harnessing the advantages of precision machining, you can elevate the accuracy, efficiency, quality, and cost-effectiveness of your operations, leading to increased growth and success in the industry.FAQ

What is precision machining?

Precision machining is a manufacturing process that utilizes computer-controlled machinery to produce high-precision parts with enhanced accuracy, speed, and efficiency.

What are the advantages of precision machining?

Precision machining offers benefits such as increased precision and accuracy, enhanced efficiency and productivity, improved quality and consistency, cost-effectiveness, versatility, and customizability in the manufacturing process.

What industries can benefit from precision machining?

Precision machining has widespread applications across various industries, including aerospace, automotive, medical, electronics, defense, energy, and telecommunications.

How does precision machining improve quality and consistency?

Precision machining ensures that each part manufactured meets the required specifications, eliminating variations and inconsistencies that can arise from manual machining methods. It also reduces the occurrence of defects and errors, resulting in higher-quality end products.

Is precision machining cost-effective?

Yes, precision machining offers cost-effectiveness in the manufacturing process. While there may be an initial investment in CNC machinery and programming, the long-term savings outweigh the costs. Precision machining reduces labor costs, minimizes material wastage, and saves time and resources through improved efficiency and reduced defects.

Can precision machining work with different materials?

Yes, precision machining can work with a wide range of materials, including metals, plastics, and composites, offering businesses the flexibility to choose the most suitable material for their specific application.

How does precision machining improve efficiency and productivity?

Precision machining, specifically CNC machining, eliminates the need for manual labor and reduces the risk of errors. CNC machines can operate 24/7, ensuring continuous production and faster turnaround times. Automated tool changers and advanced programming capabilities further enhance efficiency and productivity in the manufacturing process.

Are there advancements in precision machining?

Yes, precision machining is constantly evolving with advancements in technology and techniques. Multi-axis CNC machines, high-speed machining, computer-aided design (CAD) software, automation, robotics, and advancements in tooling and materials are continuously improving the efficiency and capabilities of precision machining.

What is the future of precision machining?

The future of precision machining holds even more cutting-edge uses and advancements that will further revolutionize manufacturing processes. As precision machining continues to advance and evolve, businesses can expect more innovative solutions that will further amplify their success in the manufacturing industry.

What are the Benefits of Using a CNC Machine for Precision Machining?

Using a CNC machine for precision machining offers numerous benefits to businesses. With this advanced technology, companies can achieve high levels of accuracy, consistency, and efficiency in their manufacturing processes. From reducing human error to improving productivity, CNC machines enable faster production times and higher quality products. Moreover, can cnc machines generate profit?? Absolutely! They facilitate cost savings through reduced waste materials, faster project completion, and increased production capacity, ultimately resulting in improved profitability for businesses.