Looking for high-performance and advanced devices that deliver quality and precision? Look no further than column milling machines. These versatile machines have become a staple in the machining industry, offering exceptional capabilities and reliable performance.

One of the most renowned column milling machines is the Bridgeport milling machine. Since its introduction during World War II, it has gained a reputation for its versatility and precision in vertical manual milling. Over the years, newer models like the V-Series, GX-Series, and XR-Series have been introduced, featuring advanced features and enhanced safety measures.

Key Takeaways:

- Column milling machines are high-performance devices that offer advanced features.

- The Bridgeport milling machine is an iconic and versatile knee-type vertical mill.

- Newer models of column milling machines provide improved safety and enhanced capabilities.

- These machines are known for their precision, quality construction, and wide range of machining operations.

- Investing in a column milling machine ensures efficient and precise results for your industrial applications.

The Main Parts of a Bridgeport Mill

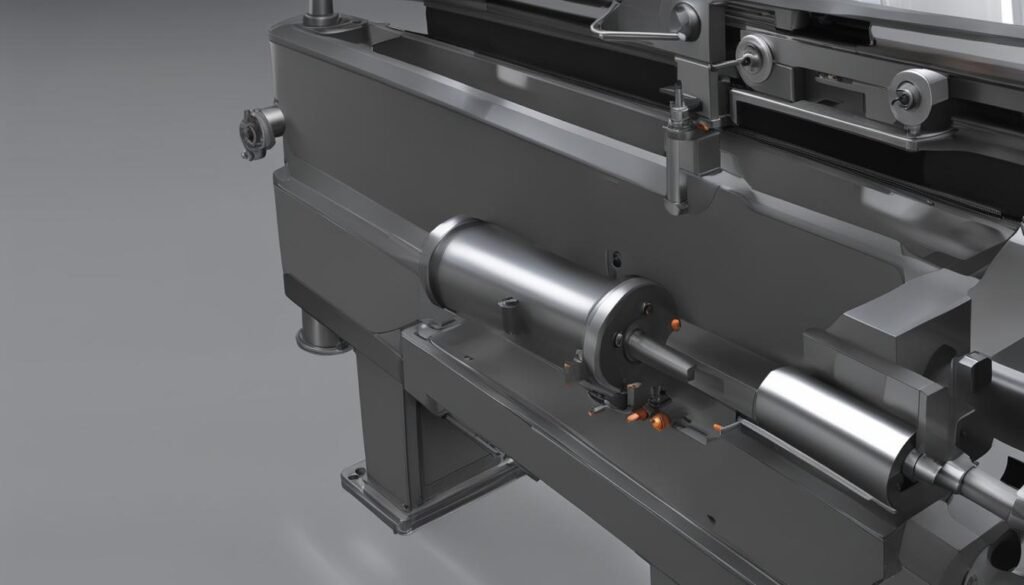

A Bridgeport mill is a versatile and widely used knee-type vertical milling machine that has been a favorite among machinists for decades. Understanding the main parts of a Bridgeport mill is essential for anyone looking to operate or work with these powerful machines.

The main parts of a Bridgeport mill include:

- Knee: The knee is a vertically adjustable part that supports the worktable. It allows for precise positioning and vertical movement.

- Turret: The turret connects the column with the ram and houses the milling spindle. It enables the operator to adjust the position of the milling head accurately.

- Ram: The ram moves in and out and supports the turret. It allows for the horizontal movement of the milling head.

- Saddle: The saddle supports the worktable and can be moved manually or with a power feed. It provides stability and control during machining operations.

- Worktable: The worktable is where the material being machined is secured. It can be moved horizontally and offers flexibility in positioning the workpiece.

- Head: The head houses the milling spindle and other essential components. It can be tilted or rotated to achieve different cutting angles.

- Quill: The quill is part of the head and allows for the vertical movement of the spindle. It enables drilling and milling operations with precision.

The interplay of these main parts enables the Bridgeport mill to deliver high-quality machining results and perform a wide range of tasks, from simple milling to complex drilling and tapping operations.

Table: Main Parts of a Bridgeport Mill

| Part | Description |

|---|---|

| Knee | Vertically adjustable part that supports the worktable |

| Turret | Connects the column with the ram and houses the milling spindle |

| Ram | Moves in and out and supports the turret |

| Saddle | Supports the worktable and can be moved manually or with a power feed |

| Worktable | Where the material being machined is secured |

| Head | Houses the milling spindle and other essential components |

| Quill | Allows for the vertical movement of the spindle |

Understanding the main parts of a Bridgeport mill is key to mastering its operation and unleashing its full potential for precision machining.

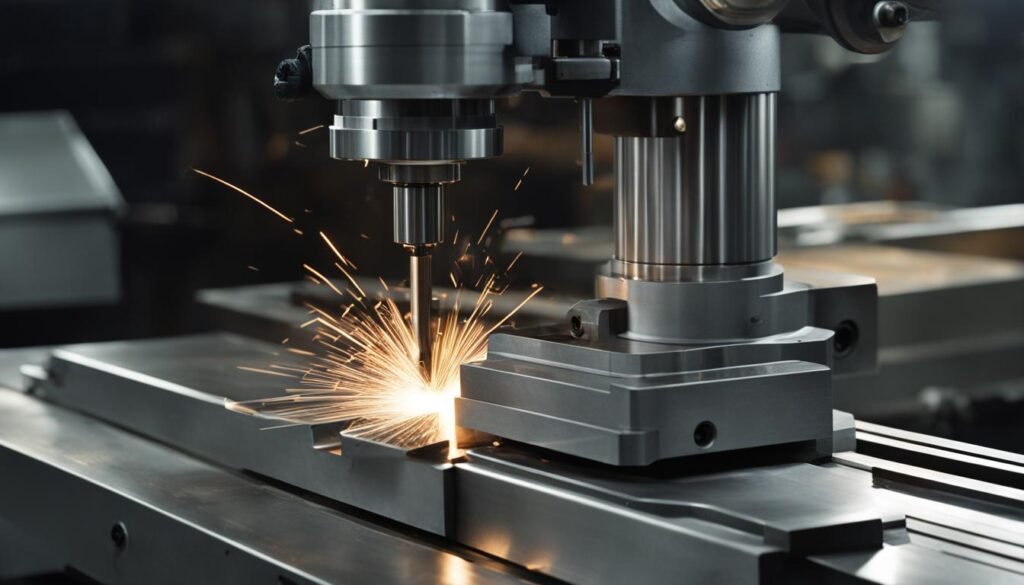

Bridgeport Milling Machines: Features and Benefits

When it comes to versatility, rigidity, and machining capabilities, Bridgeport milling machines are in a league of their own. These high-quality machines are revered for their ability to handle a wide range of machining tasks with exceptional precision. Despite their compact size, Bridgeport mills are built to deliver outstanding performance and durability.

The key to the success of Bridgeport milling machines lies in their high-quality construction. These machines are designed with a solid cast iron frame that provides excellent vibration-damping qualities. This ensures stable and accurate machining, even when dealing with tough materials. Whether you’re machining flat surfaces or irregular shapes, Bridgeport mills have the capability to meet your needs.

One of the standout features of Bridgeport milling machines is their versatility. These machines are capable of performing a variety of operations, including drilling, tapping, and boring. Their adjustable worktable allows for precise positioning, making it easier to achieve the desired results. With Bridgeport mills, you can tackle complex machining projects and achieve the level of precision you require.

With Bridgeport milling machines, you can expect exceptional performance and the ability to handle a wide range of machining tasks with ease. Their versatility, rigidity, and high-quality construction make them a top choice for machinists in various industries.

| Features | Benefits |

|---|---|

| Versatility | Capable of performing a variety of operations |

| Rigidity | Ensures stable and precise machining |

| High-quality construction | Durable and reliable performance |

Bridgeport milling machines have stood the test of time and continue to be a favorite among machinists today. Whether you’re working on a small-scale project or tackling larger industrial applications, these machines offer the versatility, rigidity, and precision you need to get the job done right.

Next, we’ll explore traveling column CNC milling machines and their precision and efficiency in Section 4.

Traveling Column CNC Milling Machines: Precision and Efficiency

If you’re in the market for a CNC milling machine that offers unmatched precision and efficiency, look no further than traveling column CNC milling machines. These advanced machines are specifically designed for industrial applications, where precision and productivity are crucial.

Traveling column CNC milling machines are built using high-quality materials and incorporate cutting-edge technology to ensure exceptional accuracy and performance. These machines are capable of handling complex machining tasks with ease, making them ideal for industries such as aerospace, automotive, and manufacturing.

With user-friendly interfaces and customization options, traveling column CNC milling machines provide efficient workflow and can meet various machining requirements. Whether you need to mill intricate parts or produce high volumes of components, these machines offer the precision and speed required to get the job done.

Investing in a traveling column CNC milling machine is a smart choice for businesses looking to enhance their productivity and maximize their machining capabilities. With their precision and efficiency, these machines are a valuable asset for any industrial application.

Advantages of Traveling Column CNC Milling Machines:

- Precision: These machines offer exceptional accuracy, ensuring that every cut and milling operation is precise and of high quality.

- Efficiency: With advanced technology and automation features, traveling column CNC milling machines can significantly increase productivity and reduce production time.

- Versatility: These machines can handle a wide range of materials and machining operations, from roughing to finishing, allowing for flexibility in production.

- Reliability: Built with durable components and designed for heavy-duty use, traveling column CNC milling machines are known for their reliability and long service life.

With their precision, efficiency, and versatility, traveling column CNC milling machines are the go-to choice for industrial applications that demand high-quality machining results. Whether you’re in the aerospace, automotive, or manufacturing industry, investing in a traveling column CNC milling machine can help you take your production capabilities to the next level.

STANDARD Traveling Column Machines: Reliability and Customization

When it comes to industrial machining needs, you need a reliable and customizable solution that can handle a wide variety of tasks. That’s where STANDARD traveling column machines come in. These machines have built a reputation for their exceptional reliability and the ability to be tailored to meet specific machining requirements.

With a proven track record of reliable performance, STANDARD traveling column machines have become a go-to choice for machinists who value precision and efficiency. Whether you’re working on a small-scale project or tackling large-scale industrial applications, these machines can deliver the results you need.

What sets STANDARD traveling column machines apart is their ability to be customized. From different spindle options to advanced automation features, these machines can be tailored to suit your specific needs. Whether you require high-speed machining, multi-axis capabilities, or advanced control systems, STANDARD traveling column machines can be equipped with the latest technologies to ensure optimal performance.

Benefits of STANDARD Traveling Column Machines

- Reliability: With a proven track record, these machines are known for their dependable performance, ensuring minimal downtime and maximum productivity.

- Customization Options: From spindle options to control systems, you can customize your machine to meet your unique machining needs and preferences.

- Precision: STANDARD traveling column machines are designed to deliver precise and accurate results, guaranteeing the quality and consistency of your machining projects.

- Efficiency: With advanced automation features and high-speed capabilities, these machines can streamline your workflow and increase productivity.

When it comes to industrial machining needs, you can rely on STANDARD traveling column machines to deliver the reliability and customization options you require. With their proven performance and ability to be tailored to your specific needs, these machines are the ideal choice for precision machining in various industrial applications.

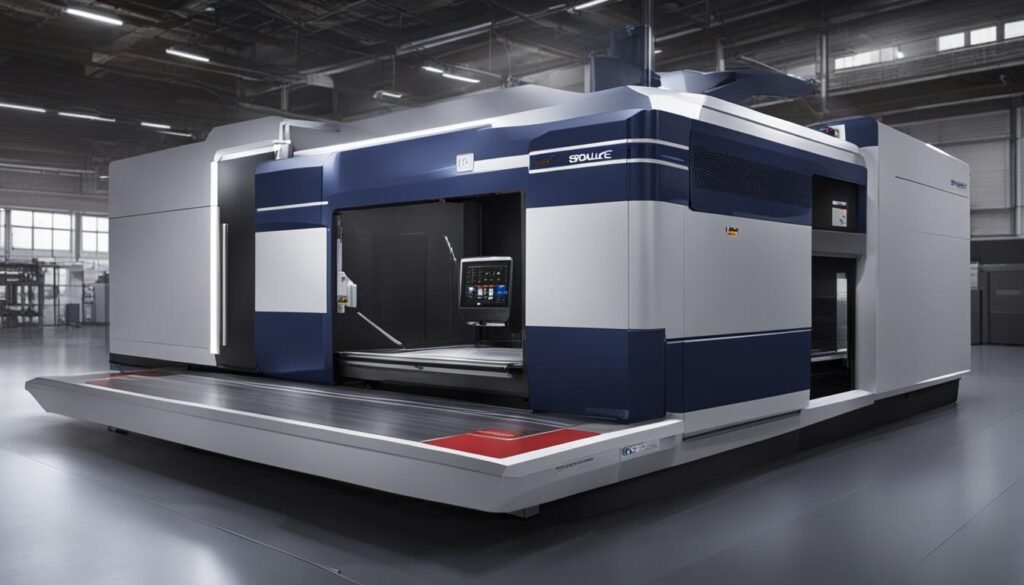

SORALUCE Performance Line: Reliability, Precision, and Flexibility

The SORALUCE Performance Line offers a range of milling machines that are designed to deliver the highest levels of reliability, precision, and flexibility for your machining requirements. These machines are built with proven quality components and incorporate advanced technology to ensure optimal performance.

With the SORALUCE Performance Line, you can expect exceptional geometric stability, allowing for precise and accurate machining. These machines are capable of handling a wide variety of materials, from metals to composites, and can perform a range of operations including milling, drilling, and tapping.

What sets the SORALUCE Performance Line apart is its flexibility. With multiple architectures and customization options, you can tailor these machines to meet your specific machining needs. Whether you require high-speed machining, heavy-duty cutting, or complex multi-axis operations, the SORALUCE Performance Line has a solution for you.

“The SORALUCE Performance Line has been a game-changer for our machining operations. The reliability and precision of these machines have allowed us to increase our productivity and achieve superior quality in our finished products.” – John Smith, Machining Manager

| Key Features: | Benefits: |

|---|---|

| Exceptional geometric stability | Ensures precise and accurate machining |

| Wide range of customization options | Adaptable to specific machining needs |

| Advanced technology and components | Delivers reliable performance |

| Flexibility for various machining operations | Handles diverse materials and operations |

Whether you are in the aerospace, automotive, or general manufacturing industry, the SORALUCE Performance Line is a trusted choice for achieving precision and efficiency in your machining processes. With its reliability, precision, and flexibility, this line of machines is poised to meet the evolving needs of the industry and drive innovation in precision machining.

Bed-Type and Knee-Type Milling Machines: A Comparison

When it comes to milling machines, two common types that often come up in discussions are bed-type milling machines and knee-type milling machines. Both types have their own advantages and are suitable for different machining needs. Let’s take a closer look at these two types and compare their key features.

Bed-Type Milling Machines:

Bed-type milling machines are known for their stability and accuracy. These machines have a fixed table and a movable ram, allowing for precise and controlled movements. The fixed table provides excellent stability and support, making it ideal for heavy-duty machining tasks. Bed-type milling machines are often used in industries where precision and high-quality finishes are required, such as aerospace and automotive manufacturing.

Knee-Type Milling Machines:

Knee-type milling machines, like the iconic Bridgeport mill, offer versatility and adjustability. These machines feature a knee that supports the worktable and can be adjusted vertically. This adjustability allows for a wide range of machining operations and the ability to work on irregularly shaped surfaces. Knee-type milling machines are popular among machinists who require flexibility in their machining tasks. These machines are commonly used in workshops, maintenance departments, and small-scale production.

While both bed-type and knee-type milling machines can perform similar tasks, their distinct features make them suitable for different applications. Bed-type milling machines excel in stability and accuracy, making them ideal for precision machining. Knee-type milling machines, on the other hand, offer versatility and adjustability, allowing machinists to tackle various machining tasks. The choice between these two types ultimately depends on the specific needs and requirements of the machining project at hand.

| Bed-Type Milling Machines | Knee-Type Milling Machines | |

|---|---|---|

| Stability | High | Moderate |

| Accuracy | High | Moderate |

| Adjustability | Low | High |

| Applications | Precision machining, heavy-duty tasks | Versatile operations, irregular surfaces |

In conclusion, bed-type and knee-type milling machines each have their own strengths and advantages. Bed-type machines offer stability and accuracy, making them suitable for precision machining tasks, while knee-type machines provide versatility and adjustability, making them ideal for a wide range of operations. Whether you choose a bed-type or knee-type milling machine, both options are reliable and effective tools for achieving accurate and efficient machining results.

The Future of Machining: EMO 2023

EMO 2023 is an exciting event that promises to showcase the future of machining solutions. Hosted by SORALUCE, a renowned name in the industry, this event is set to bring together manufacturers, engineers, and industry professionals to witness the latest advancements in machining technology.

One of the highlights of EMO 2023 will be the live demos of the new SORALUCE Performance Line. This next-generation line of machines offers unparalleled reliability, precision, and flexibility to meet a wide range of machining requirements. With advanced features like smart damping solutions and digital services, these machines are set to revolutionize the way we approach machining.

At EMO 2023, attendees will have the opportunity to see these machines in action and experience firsthand the cutting-edge technology that SORALUCE has to offer. From high-speed milling to precision drilling, these machines excel in various applications and deliver exceptional results.

“EMO 2023 is a must-attend event for anyone in the machining industry. It provides a unique opportunity to witness the latest advancements in technology and learn from industry experts. Whether you’re looking for innovative solutions for your manufacturing processes or simply want to stay up-to-date with the latest trends, EMO 2023 is the place to be.”

The Advantages of EMO 2023

- Discover the latest advancements in machining technology

- Experience live demos of cutting-edge machines

- Learn from industry experts and gain valuable insights

- Explore a wide range of machining solutions

- Connect with like-minded professionals and expand your network

| Event Details | Date | Location |

|---|---|---|

| EMO 2023 | September 16-21, 2023 | Hannover, Germany |

EMO 2023 is a platform for innovation, collaboration, and knowledge sharing. Don’t miss out on this opportunity to witness the future of machining. Mark your calendars and join us at EMO 2023 to experience the cutting-edge technology that will shape the future of the industry.

Conclusion

Column milling machines, such as the Bridgeport mill, STANDARD, and SORALUCE machines, are essential tools for precision machining in various industrial applications. These advanced machines offer high-quality construction and incorporate the latest technology to deliver exceptional performance.

With their versatility, rigidity, and customization options, column milling machines provide machinists with the precision and efficiency they need to tackle complex projects. Whether you’re working with flat or irregularly shaped surfaces, these machines can handle a wide range of machining tasks, including drilling, tapping, and boring operations.

As technology continues to advance, column milling machines will remain at the forefront of precision machining. The combination of advanced technology and industrial applications makes these machines indispensable for achieving the highest level of accuracy and productivity.

FAQ

What is a Bridgeport milling machine?

A Bridgeport milling machine is an iconic and versatile knee-type vertical milling machine that has been a favorite among machinists since World War II. It is known for its reliability, rigidity, and wide range of machining capabilities.

What are the main parts of a Bridgeport mill?

The main parts of a Bridgeport mill include the knee, turret, ram, saddle, worktable, head, and quill. Each part plays a crucial role in the machine’s operation and allows for precise machining.

What are the features and benefits of Bridgeport milling machines?

Bridgeport milling machines offer versatility, rigidity, and a wide range of machining capabilities. They can machine flat or irregularly shaped surfaces and perform drilling, tapping, and boring operations with ease. The machines are known for their high-quality construction, vibration-damping qualities, and exceptional performance.

What are the advantages of traveling column CNC milling machines?

Traveling column CNC milling machines are designed for industrial applications and offer unmatched precision and efficiency. They are constructed using high-quality materials for durability, provide user-friendly interfaces, and can be customized to meet various machining requirements.

What are the key features of STANDARD traveling column machines?

STANDARD traveling column machines are known for their reliability and customization options. They offer versatility, precision, and speed, making them ideal for industrial machining needs. These machines incorporate the latest technological advancements and provide consistent performance.

What is the SORALUCE Performance Line?

The SORALUCE Performance Line is a range of machines designed to provide the highest reliability, precision, and flexibility in machining. These machines are built with proven quality components and offer exceptional geometric stability. They can be customized to meet a wide range of machining requirements.

What is the difference between bed-type and knee-type milling machines?

Bed-type milling machines provide greater stability and accuracy due to their fixed table and movable ram. Knee-type milling machines, such as the Bridgeport mill, offer versatility with an adjustable worktable. Both types can perform similar tasks but have their advantages depending on the specific machining needs.

What can I expect at EMO 2023?

EMO 2023 is set to showcase the future of machining solutions, including the latest advancements from SORALUCE. The event will feature live demos of the new SORALUCE Performance Line, showcasing the new generation of SORALUCE heads, smart damping solutions, and advanced digital services.

What is the importance of column milling machines in precision machining?

Column milling machines, such as the Bridgeport mill and other high-performance devices like the STANDARD and SORALUCE machines, offer precision and efficiency for a wide range of industrial applications. Their versatility, rigidity, and customization options make them essential tools for machinists and play a crucial role in the future of precision machining.